We do the darnedest things!, as we have been told more than once. So why stop now.

We got a wild hair, and decided we had a paver stone pad that begged for some kind of artful adornment. After scratching our heads a bit, and pondering the self-made dilemma, we decided that special something should be a sundial.

Ok, I know, now I’ve got you scratching your head, but stay with me. This sundial would not only read time via shadows, but it would be a 6′ circle made from re-bar (thank you, Pat & Leonard). So we did a bit of astrophysics to calculate the longitude / latitude for our elevation to determine proper degree of alignment for the numbers, and appropriate angle and height of the gnomon (you know, that angled piece that projects the shadows).

We built a jig made up of spaced ‘bumpers’ to cold-form the 1/2″ rebar into a perfect 6′ circle. As we bent it around, the re-bar resisted, so we had to convince it to conform to our whim with a helper bar and inch-winch, putting ‘keeper’ bumpers on the outside to contain the re-bar.

It was definitely a learning experience as the re-bar let loose a couple time. John has the bruises to add insult to injury. The 3rd time was the charm, making it easier for the inside 5’2″ rebar inner circle. By the time we bent the 2nd circle we started putting straps around the circle such that we could safely flip it to weld the opposite side, hoping for no more ‘un-furling of the re-bar’ incidents.

With the rings bent, welded, and ground, we were ready to undertake the roman numerals. We cut and ground the 16- I’s, and built a jig for the angled X’s and V’s.

Then welded them together, and ground them.

Using a protractor, a string and our calculations we measured the angles for placement of our clock face roman numerals – 11 am and 1 pm at 8.64 degrees, 10 am and 2pm at 18.13 degrees, etc. Then we individually welded our numbers into position.

For added strength we welded 5 re-bar support struts from the center to the OD of the inside ring, one of which the gnomon will mount on.

After a lot of welding and grinding, we are looking toward the embellishment phase. The clock face will be powder coated a brick red color, so to make it pop we decide to add a removable adornment at the bottom. It will be mounted on bands, adding strength to the bottom of the sundial, and tying the bottom rings together. So that it can be removed to be painted another color (black) we have to get creative on a method to remove.

We individually cut, bent and ground 1/4″ bar stock to make letters spelling out ‘HAPPY JACK’.

Individual letters are cut, ground and formed to shape.

To tie the letters together we attach them to a wire to hold them in place and make them removable, adding washers to bolt to the bands on the clock face.

Are you staying with me? Whew! I know.

Aside from the clock itself, some of the most pondering came from trying to figure out how to make the HAPPY JACK and gnomon removable, and seamlessly elegant without clap trap.

Finally we get to the gnomon part and speeding that process along, we cut the gnomon with a plasma cutter and weld it to re-bar, attaching metal tabs to the clock face and bottom of the gnomon.

And wa-la, a conversation piece is born.

We had it powder coated at Arizona Powdercoat (on Washington / 202 in Phoenix), who have always done a fabulous job for us, and it pops… and tells time, in it’s own artful ancient way.

For a high level history of the sundial check out my post here … https://wordpress.com/post/kritterspix.com/4441

Layout

Layout Plasma cutting metal

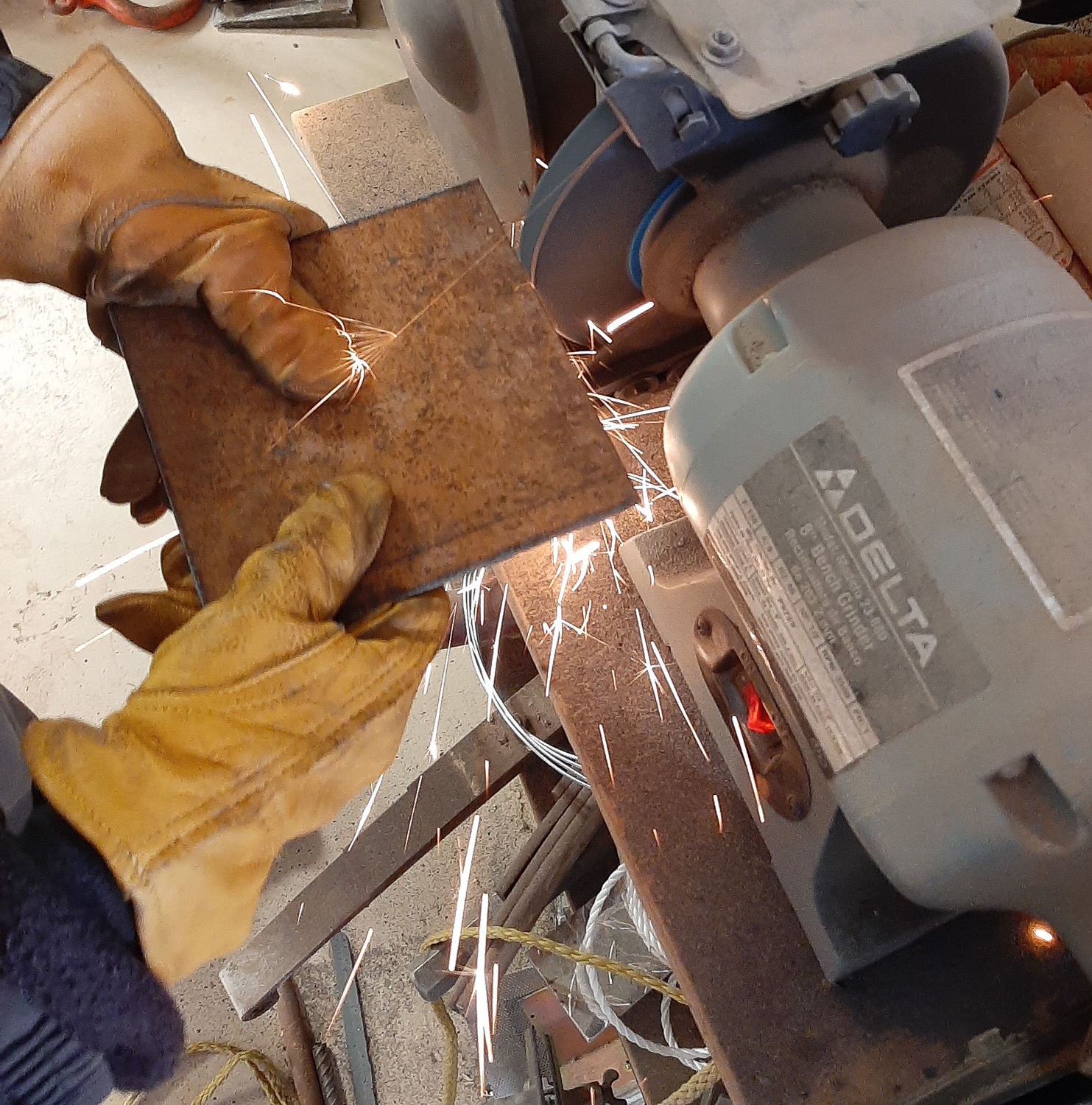

Plasma cutting metal Bench grinding sides

Bench grinding sides Angle grinding fronts

Angle grinding fronts Braising on ‘shutters’ from antique chain link

Braising on ‘shutters’ from antique chain link Arc-welding panels

Arc-welding panels Finish birdhouse – full of character and rustic charm

Finish birdhouse – full of character and rustic charm Initial Layout

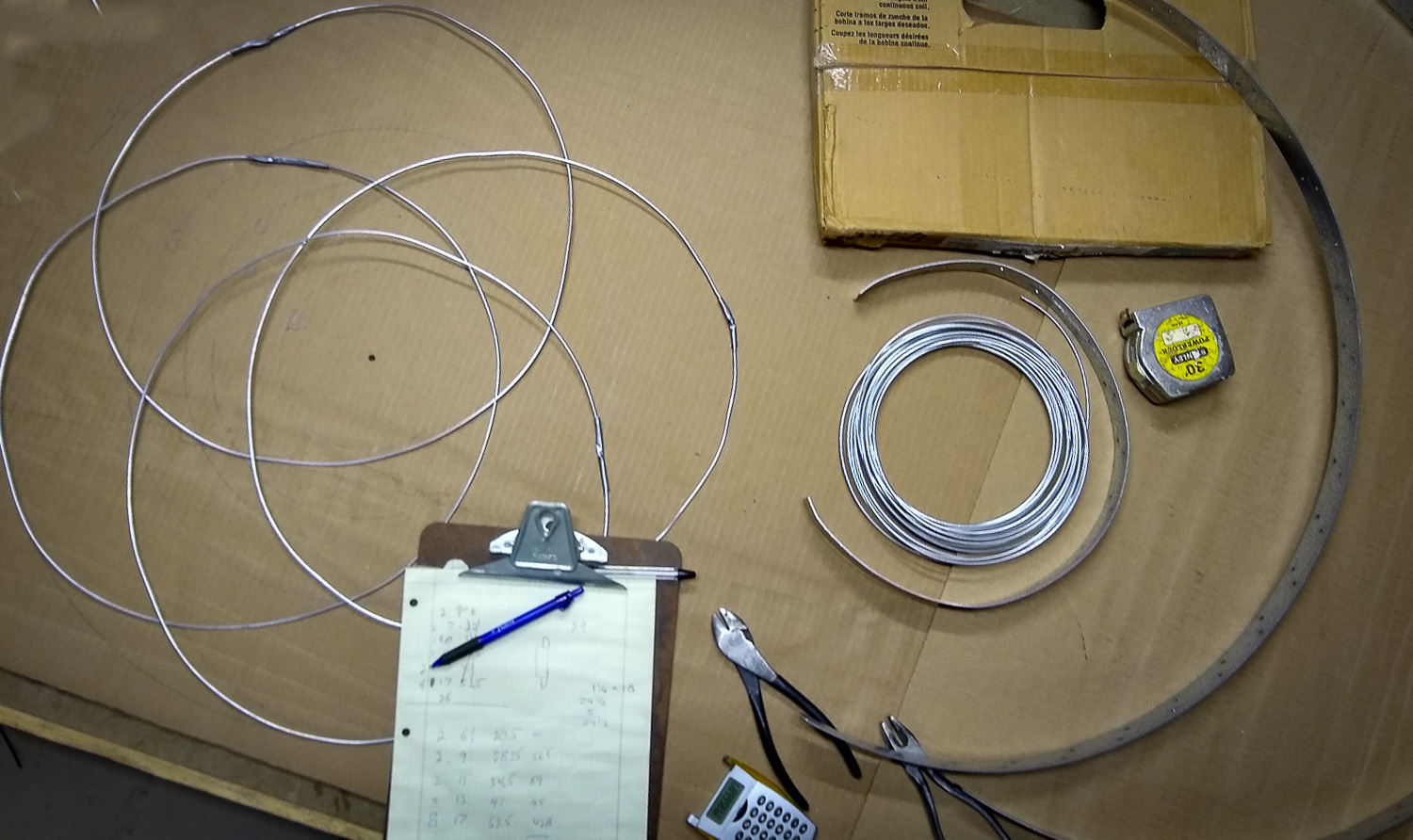

Initial Layout  Cutting strapping material for circles (rings)

Cutting strapping material for circles (rings) Preparing jig to weld rings

Preparing jig to weld rings Cutting jig template on bandsaw

Cutting jig template on bandsaw Ring set up in jig, ready to weld

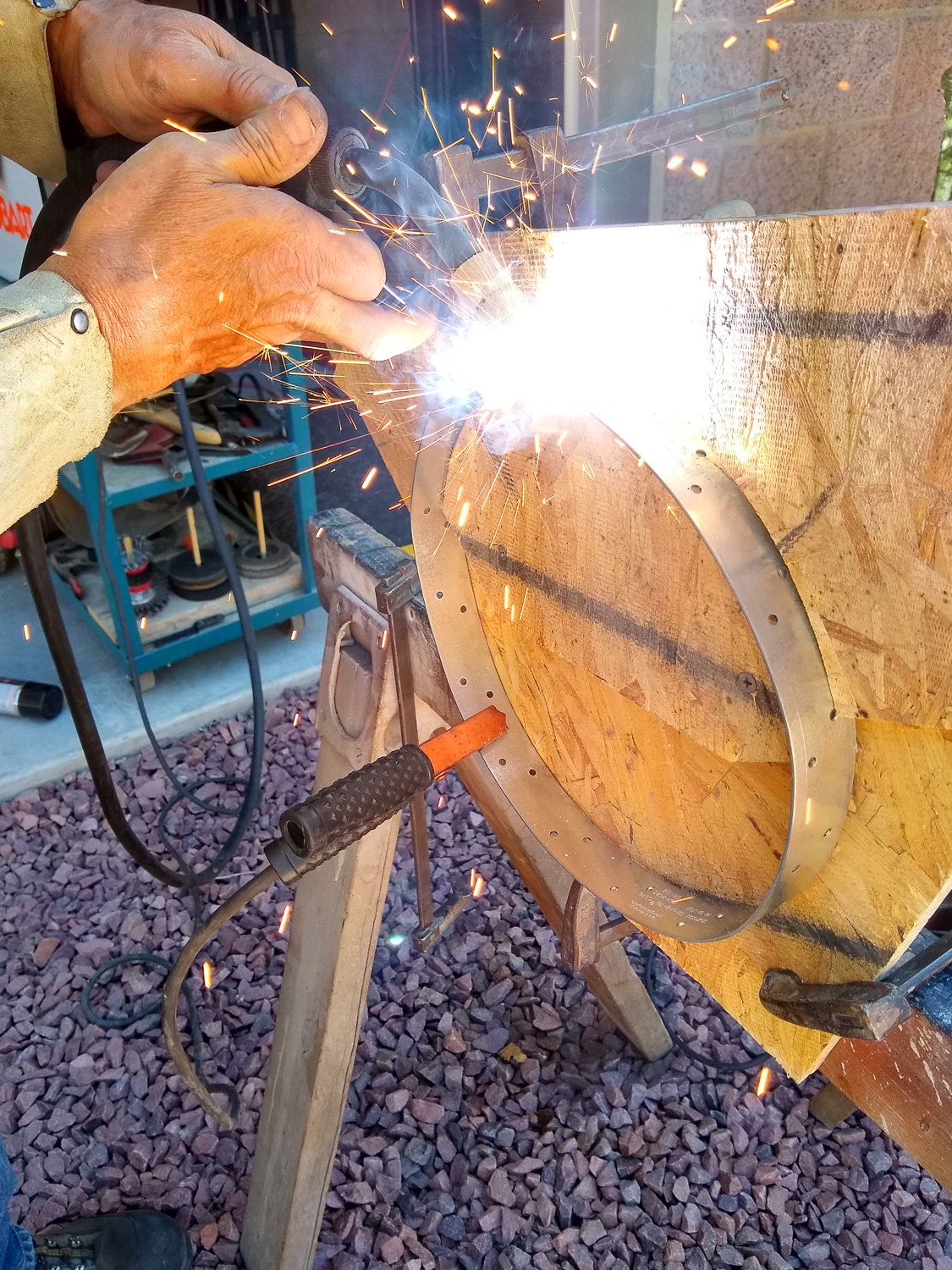

Ring set up in jig, ready to weld Welding one of many rings

Welding one of many rings Grinding one of many rings

Grinding one of many rings Grinding steel pin connectors

Grinding steel pin connectors Mock up of ring assembly

Mock up of ring assembly Welding rings together into subassembly

Welding rings together into subassembly Welding ring assembly

Welding ring assembly Grinding ring assembly

Grinding ring assembly Spraying spray tack on inner tube

Spraying spray tack on inner tube Spraying textured art paper to coat tube

Spraying textured art paper to coat tube Applying paper to tube and trimming

Applying paper to tube and trimming Painting interior of chandelier ‘shade’

Painting interior of chandelier ‘shade’ The big reveal

The big reveal

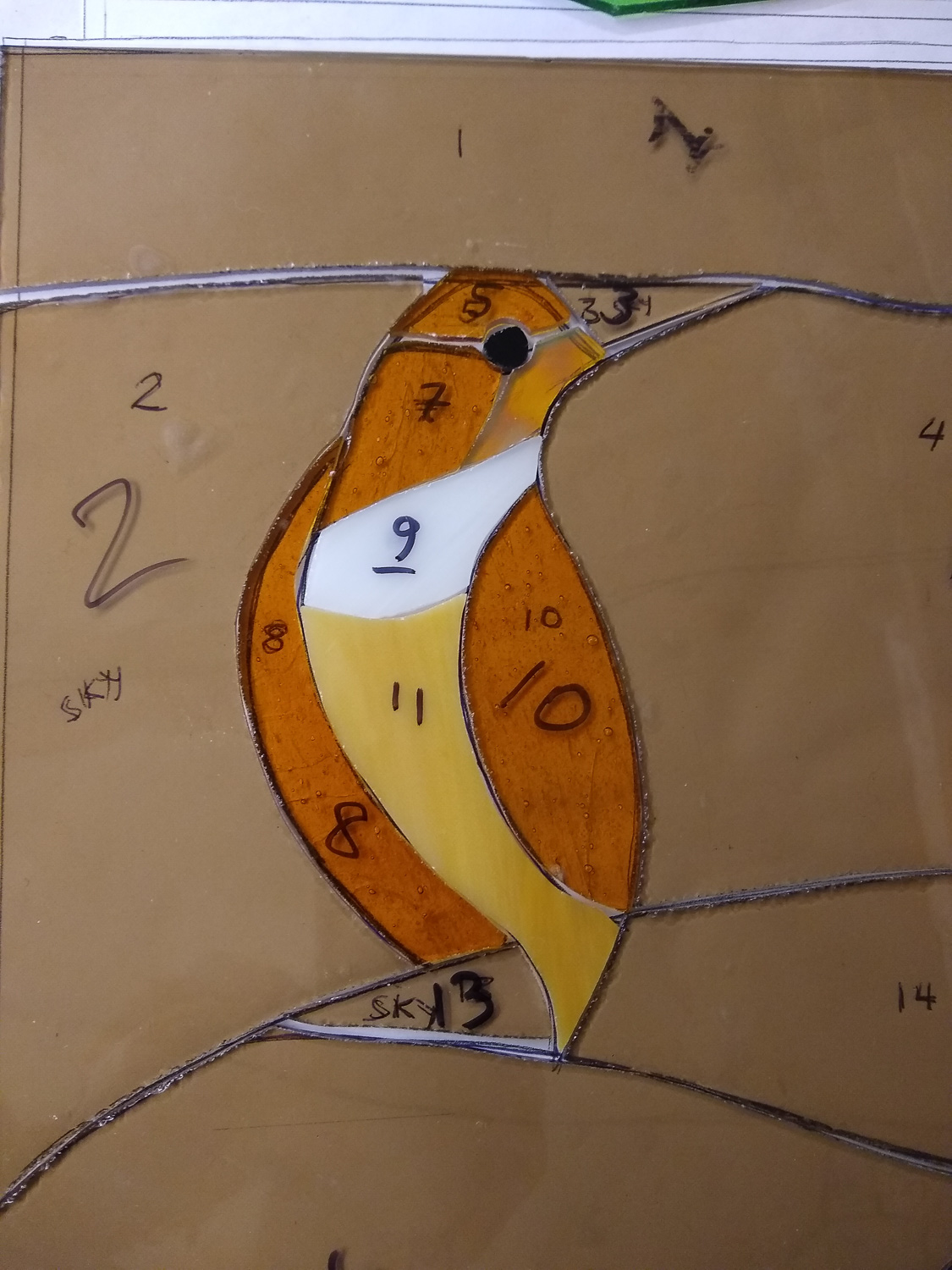

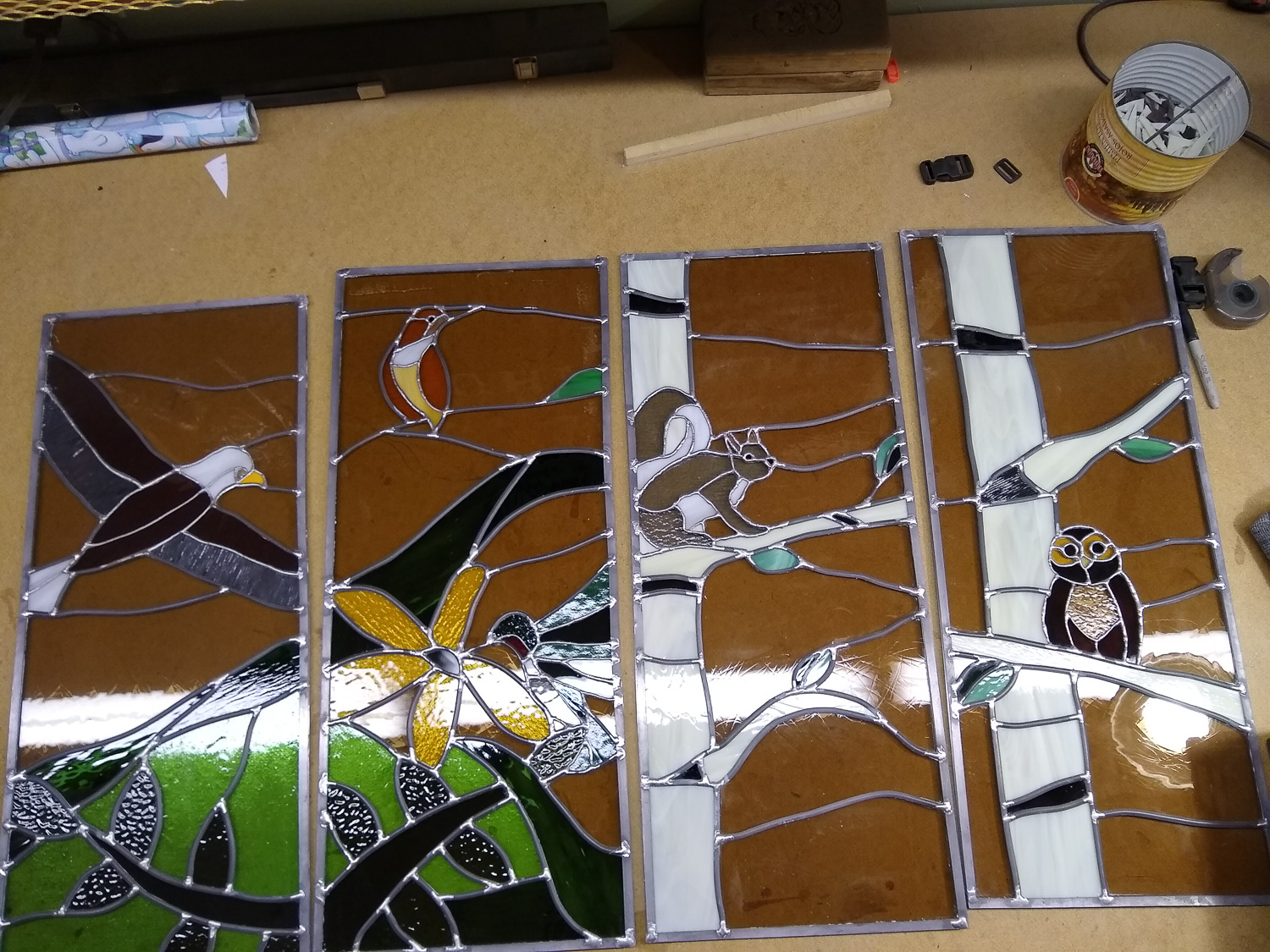

Finished stained glass panels for floor lamp

Finished stained glass panels for floor lamp Initial back of the napkin concept drawing

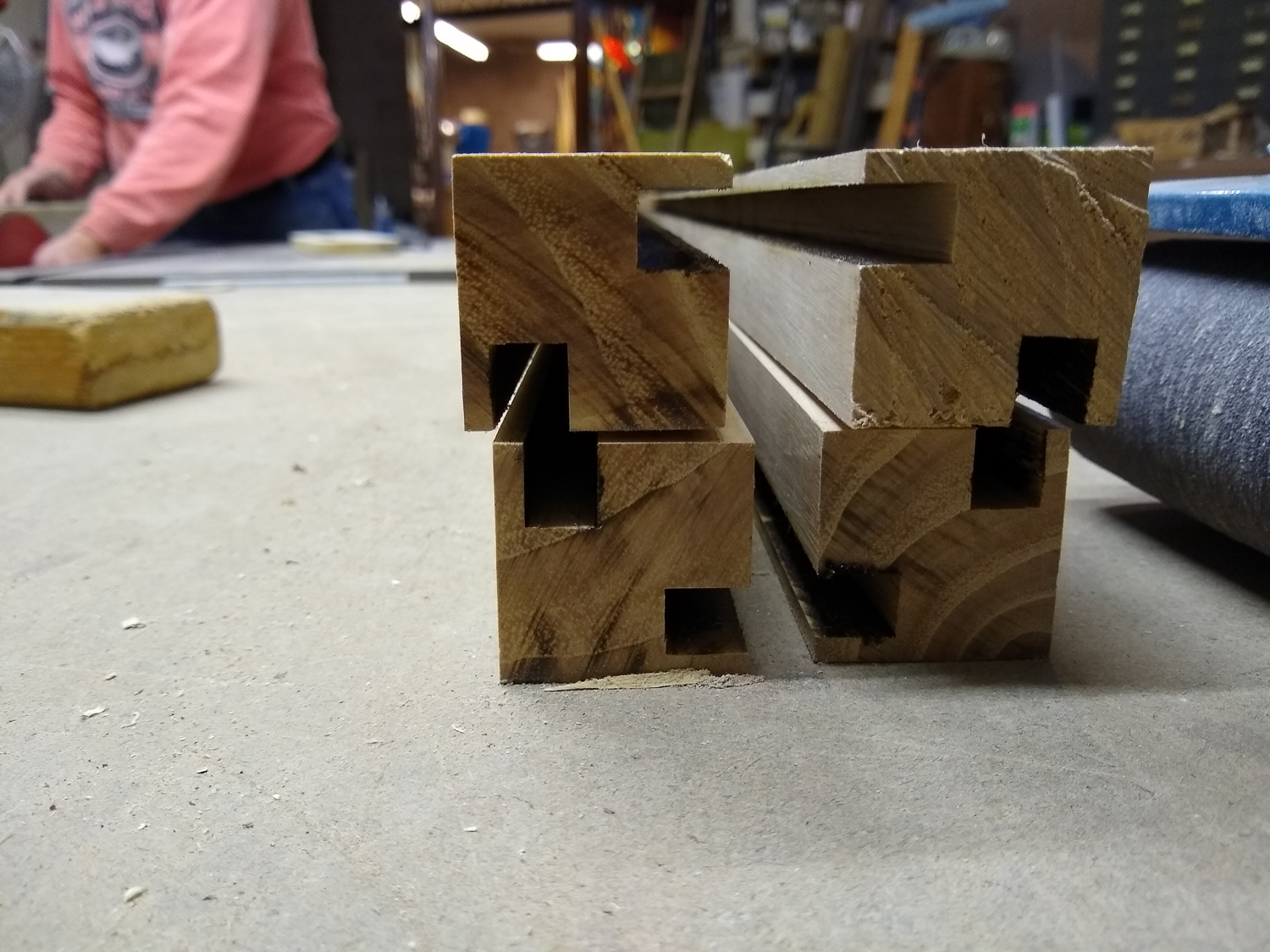

Initial back of the napkin concept drawing Making pillars for uprights to support stained glass panels

Making pillars for uprights to support stained glass panels Cut upright pillars

Cut upright pillars Trial fit of pillars to stretchers

Trial fit of pillars to stretchers Cutting list

Cutting list Glued together top section for glass panels

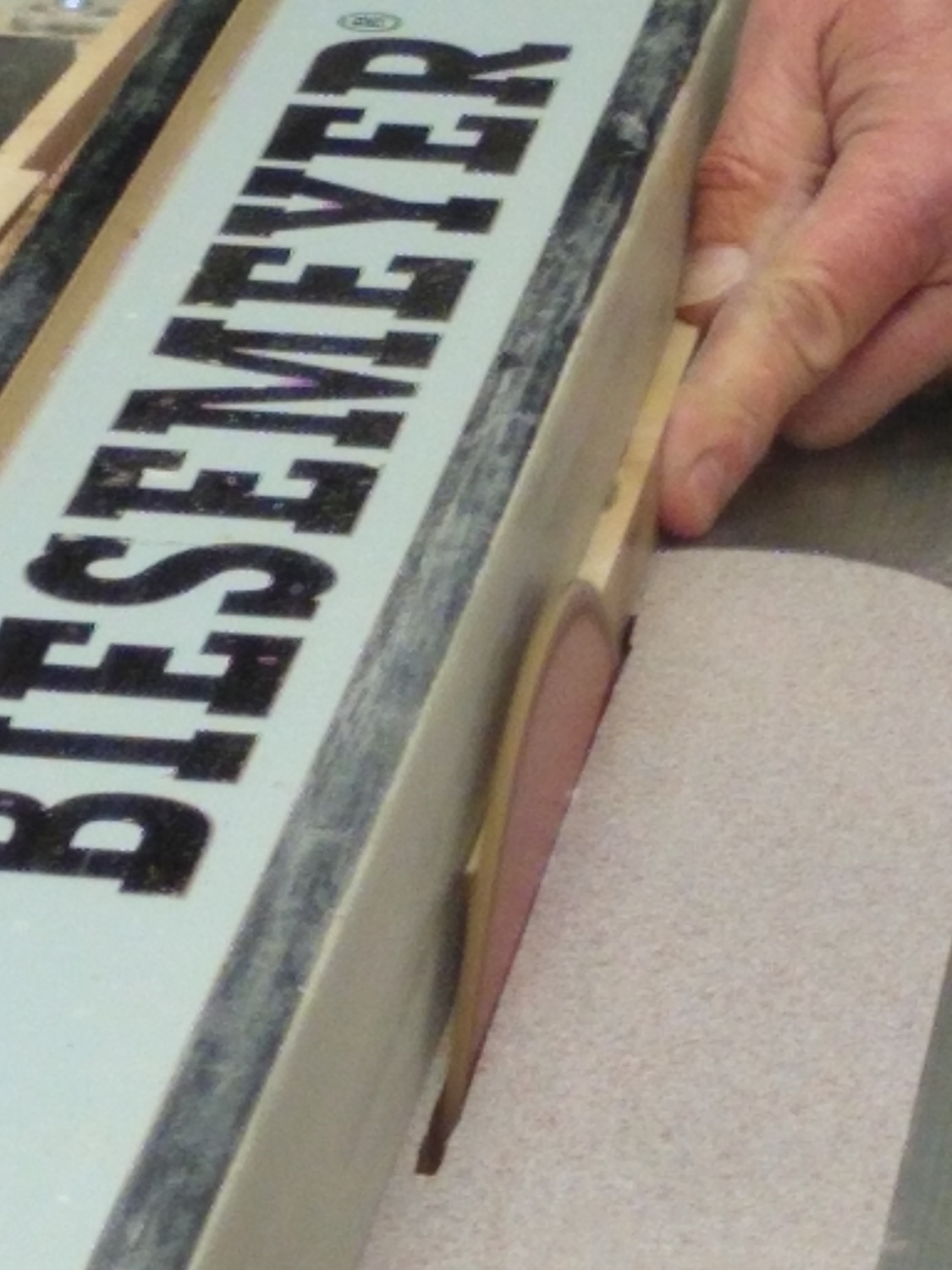

Glued together top section for glass panels Cutting mesquite inlay for shelf

Cutting mesquite inlay for shelf Gluing shelf together

Gluing shelf together Making our own baseboard molding from pecan lumber (started as tree cut from our yard)

Making our own baseboard molding from pecan lumber (started as tree cut from our yard) Cutting moulding on baseboard

Cutting moulding on baseboard  Cutting mirror for light reflection

Cutting mirror for light reflection Retainer for mirror on top stretchers

Retainer for mirror on top stretchers Trial fit of glass panels with light and mirror

Trial fit of glass panels with light and mirror Cutting birch bottom section pieces

Cutting birch bottom section pieces Cutting veneer

Cutting veneer Bits and pieces of bottom section, cut and veneered

Bits and pieces of bottom section, cut and veneered Hinge recessed for door

Hinge recessed for door Lower section glued and clamped together

Lower section glued and clamped together Gluing baseboard moulding

Gluing baseboard moulding Staining lower cabinet section

Staining lower cabinet section Spray lacquering cabinet top, bottom, and pieces

Spray lacquering cabinet top, bottom, and pieces Finished lamp with shelf pulled out

Finished lamp with shelf pulled out Finished lamp in place

Finished lamp in place

We decided to use a combination of oak and cedar for an ‘architectural’ highlight. The wood was super dry, almost kiln dried. Using the jointer we cut a flat through the 6″ – 8″ logs to clear the bark and provide a flat datum. The jointer allowed us to make parellel sides.

We decided to use a combination of oak and cedar for an ‘architectural’ highlight. The wood was super dry, almost kiln dried. Using the jointer we cut a flat through the 6″ – 8″ logs to clear the bark and provide a flat datum. The jointer allowed us to make parellel sides.